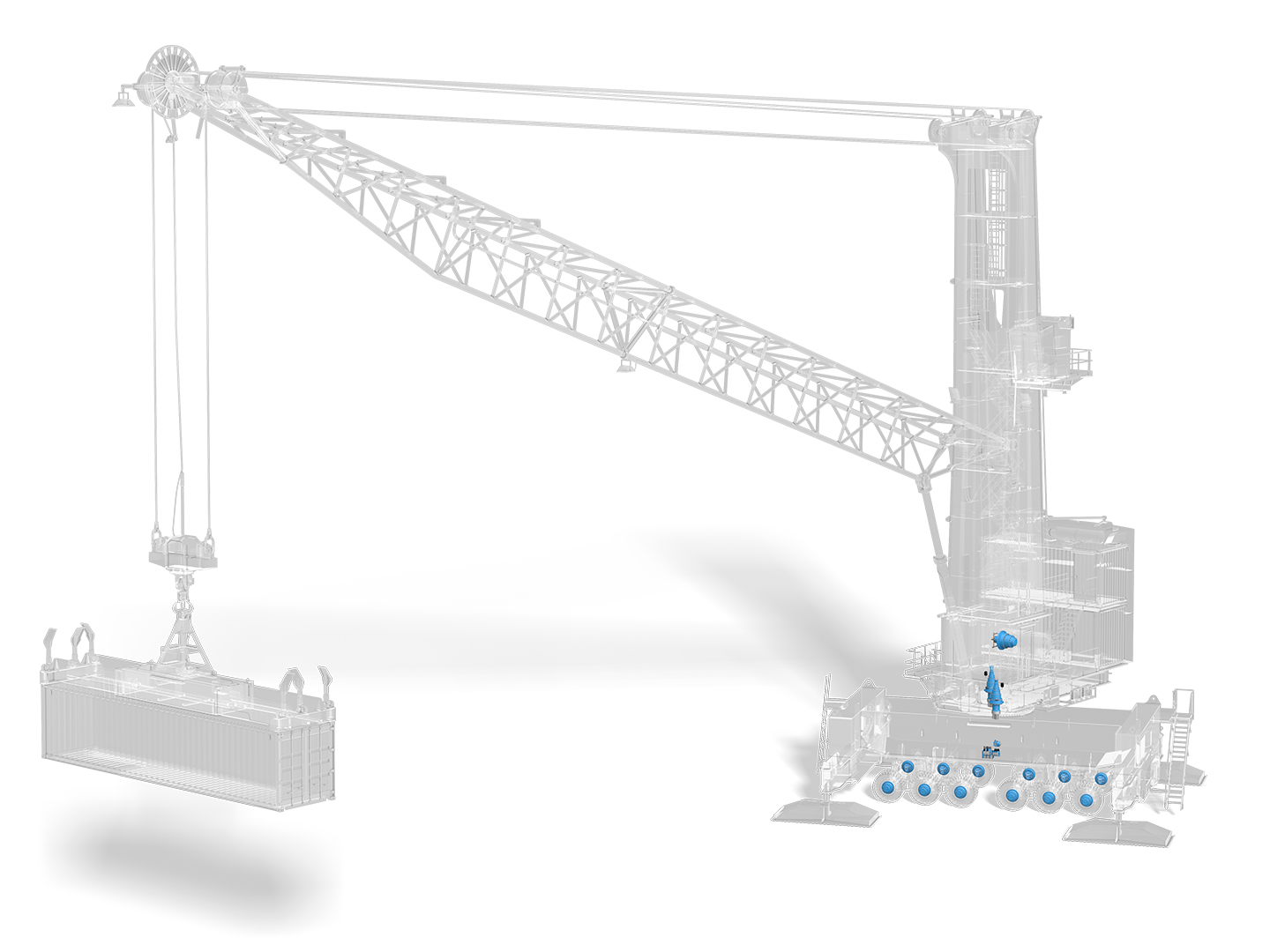

Mobile harbor cranes (MHC)

Mobile Harbor Cranes are an increasingly common replacement for static harbor cranes. Modernized and mobilized, they have become a vital crane within ports able to handle all types of goods.

Efficient, mobile and versatile, the mobile harbor crane can be used in any port for the handling of: bulk materials, steel or scrap metal, general cargo, heavy loads and containers.

MACHINE DETAILS

- High modularity

- ATEX certification

- Remote control, electronic operation

- Smooth control co improve operation functionality and accuracy

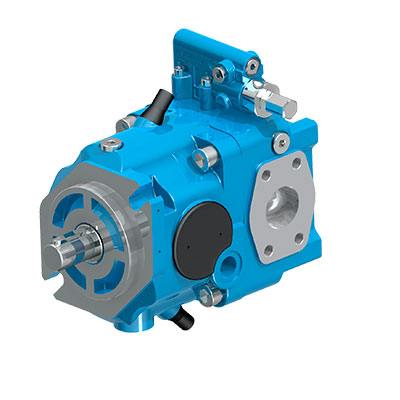

- Medium- and high-pressure options

- Fixed and variable displacement available

- Open or closed loop circuit

- ATEX certification

- Environmentally Acceptable Lubricants (EALfluids)

- Suitable for working in harsh and aggressive environments

- Marine painting cycle

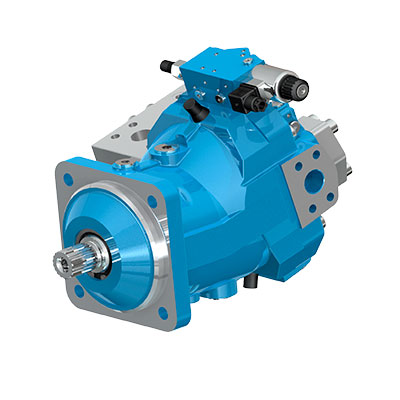

-Fixed and variable displacement

- Displacement up to 216 cc/rev

- Seven or nine piston options technologies

- Wide range of control valves

- Third-parties marine and ATEX certification

- Environmentally acceptable lubricants (EAL fluids)

- Suitable for working in harsh and aggressive environments

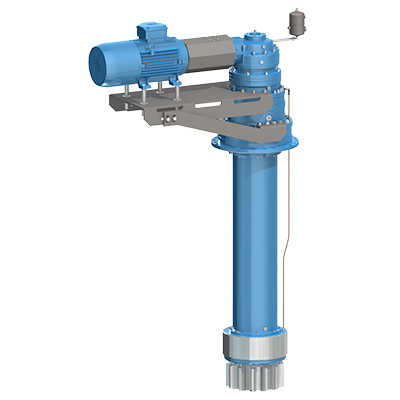

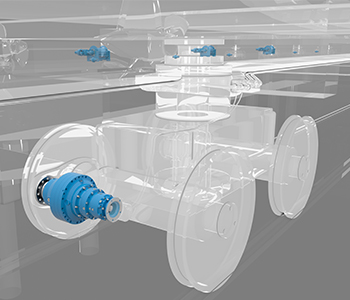

- Modular design, inline or right angle configuration

- Range of output support configurations (low angle, long and short support with eccentricity)

- Failsafe negative brakes

- Input flange for hydraulic and electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Flexible output pinion to meet customer needs

- Product marine/offshore class certification available

- Special solutions to meet requirements for low climate and ATEX certifications

- Manual disengagement device for towing

- High radial and axial load capacity bearings

- Cartridge hydraulic motors for compact layouts

- Motion control valves with different options available

- Bevel gear unit at the input for electric motor and/or cardan shaft connection available

- Special sealing system designed for severe enviromental conditions

- Hub and spindle made of strength material

(for hydraulic motors) available

- Ratio range up to 6.000:1

- Max torque up to 850 kNm

- Integrated hydraulic failsafe negative brake

Market related applications

In a shipyard luffing cranes are a fundamental piece of equipment, able to perform countless lifting and installation […]

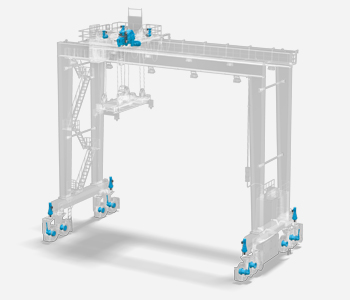

Rubber tyred gantry (RTG) cranes

With the advantage of wheels providing easy mobility, RTG cranes are harbor cranes used in intermodal operations to […]

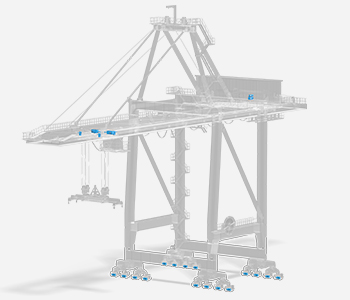

STS Cranes are large dockside gantry cranes found at container terminals for loading and unloading intermodal containers. Generally […]

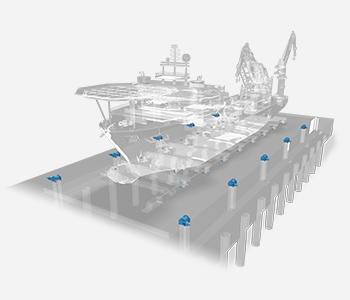

We supply dedicated solutions for the many specialized cranes that are used in large shipyards located usually near […]

We supply dedicated solutions for the many specialized cranes that are used in large shipyards located usually near […]