Luffing Crane

In a shipyard luffing cranes are a fundamental piece of equipment, able to perform countless lifting and installation tasks. Used for freight loading in ports, level-luffing cranes are also used in the construction of small to medium-sized ships. Luffing cranes incorporate traveling, slewing, luffing and lifting mechanisms and perform bucket loading, container loading as well as hook loading.

Level-luffing cranes are designed to keep the level of the hook always at the exact same height while luffing. The jib moves up and down so as to move the hook inwards and outwards from the crane base. When loads near ground level are to be moved with maximum care, level-luffing is a crucial capability, for example in shipbuilding or construction. Modern cranes now implement fixed horizontal jibs with an additional “horse head” section. In this case the interconnected action of the pivots is sufficient to maintain the level.

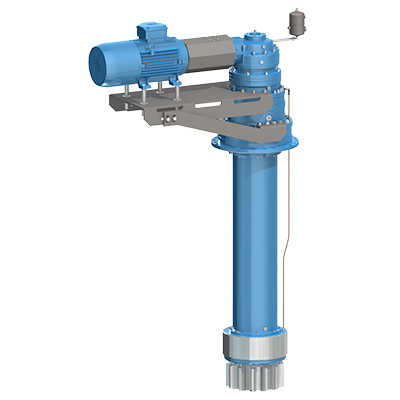

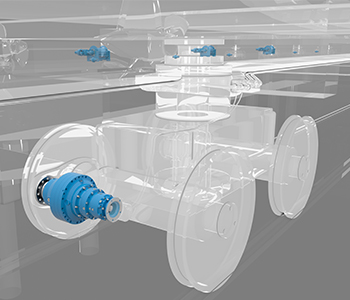

MACHINE DETAILS

- Nominal torques up to 2,170 kNm

- Multiple output shaft options

Inline and right angle configurations available

- Suitable for both hydraulic and electric motors

- Negative multidisc brake

- Modular design, inline or right angle configuration

- Range of output support configurations (low angle, long and short support with eccentricity)

- Failsafe negative brakes

- Input flange for hydraulic and electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Flexible output pinion to meet customer needs

- Product marine/offshore class certification available

- Special solutions to meet requirements for low climate and ATEX certifications

-Auxiliary drive system on board

-Marine painting

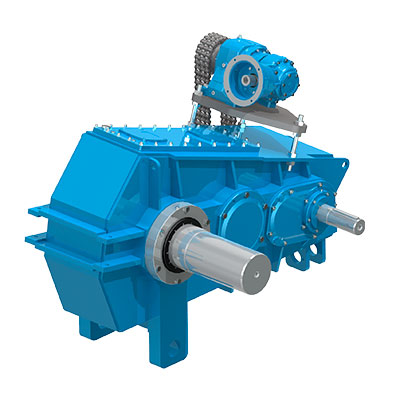

- Extensive ratio range

-Supports torque range up to 1300 kNm

-Spheroidal graphite cast iron housing

-High efficiency

-Diverse low speed shaft options

-Premium sealing

-Reliable operation

- Nominal torques up to 26,000 Nm

- Inline and right angle configurations available

- Suitable for both hydraulic and electric motors

- Integrated motor adaptor

- Negative multidisc brake

Market related applications

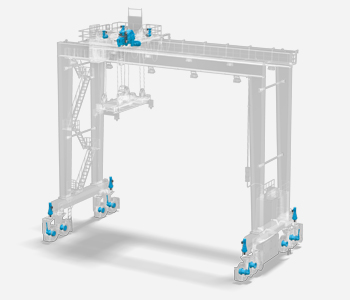

Rubber tyred gantry (RTG) cranes

With the advantage of wheels providing easy mobility, RTG cranes are harbor cranes used in intermodal operations to […]

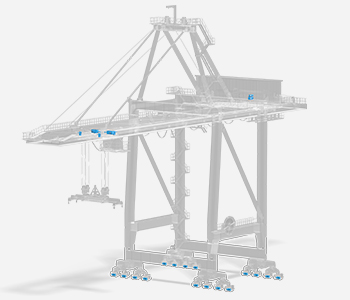

STS Cranes are large dockside gantry cranes found at container terminals for loading and unloading intermodal containers. Generally […]

Mobile Harbor Cranes are an increasingly common replacement for static harbor cranes. Modernized and mobilized, they have become […]

We supply dedicated solutions for the many specialized cranes that are used in large shipyards located usually near […]

We supply dedicated solutions for the many specialized cranes that are used in large shipyards located usually near […]