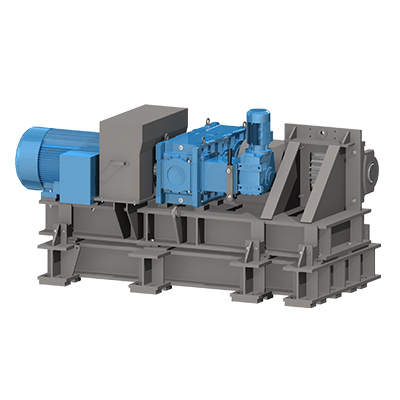

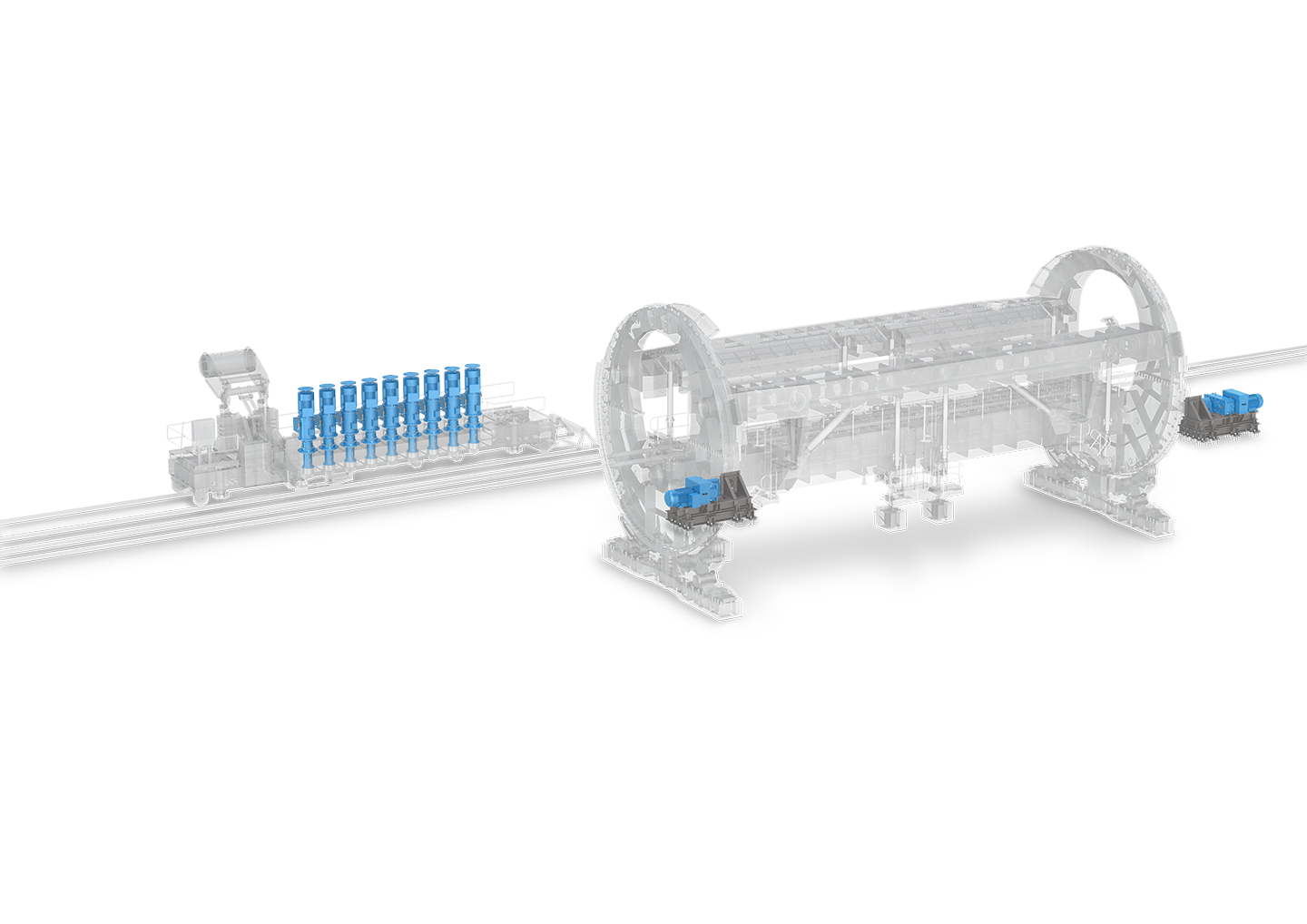

Wagon tipplers and positioners

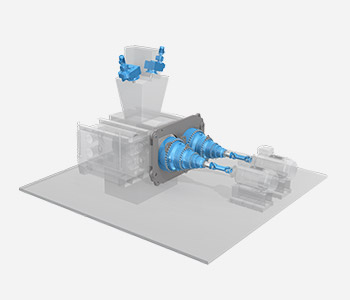

Wagon tipplers are used to unload bulk material from wagons, including coal, coke, lignite, iron ore, limestone, dolomite, and others. A complete wagon tippler system includes the positioning system, car dumper, and underground hopper along with feeders below the hopper to release bulk material. The wagon is positioned in the tippler with special positioner drives, VFD controlled using a rack-and-pinion system. Alternatively, a wire rope cable-and-drum arrangement can be used. The wagon is dumped using a specific heavy-duty rack-and-pinon drive to position it downward in the machine pit.

Depending on the application, this machine can be designed with a single, tandem, triple, or quadruple dumper frame. Every wagon tippler system is engineered to meet customer needs based on the type of bulk material that will be unloaded.

MACHINE DETAILS

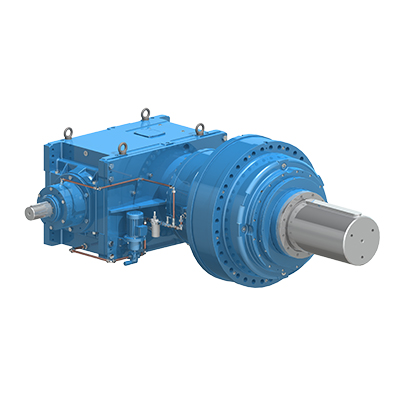

- Supports torque range up to 1300 kNm

- Spheroidal graphite cast iron housing

- High efficiency

- Premium sealing

- Reliable operation

- Low noise

- Robust design

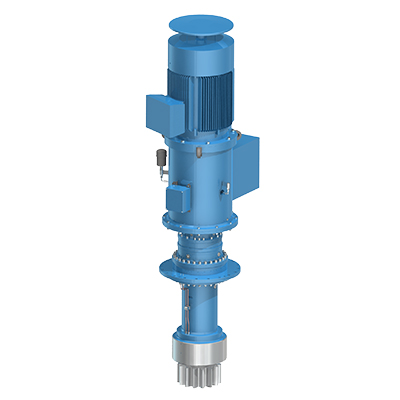

- Reliable operation, engineered for harsh conditions

- Spheroidal graphite cast iron housing for low-temperature applications

- Custom-made output support and pinions

- Supports torque range up to 2200 kNm

- Increased thermal capacity due to shared oil chamber

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Low noise

- Customized male shaft with keyway

Market related applications

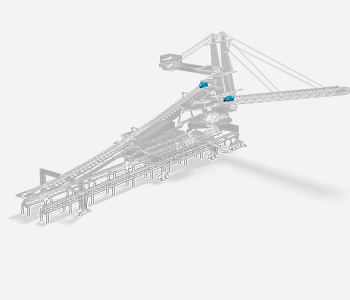

Large-sized equipment used in shipyards to load and unload solid, bulk material such as iron ore, coal, fertilizer, grain, […]

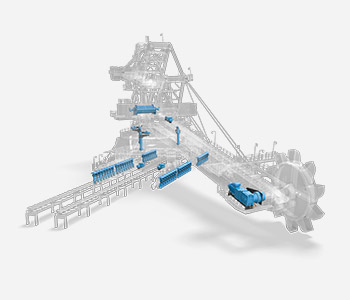

These versatile machines operate as both stacker and reclaimer, stacking material in stockpiles and reclaiming loads with a bucket […]

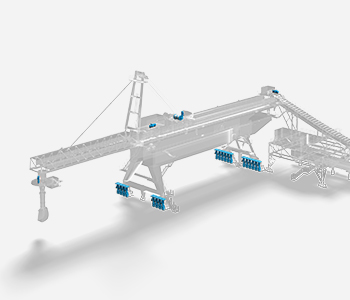

Conveyors are the workhorse of mineral handling, often used in dry processing plants where they play a key […]

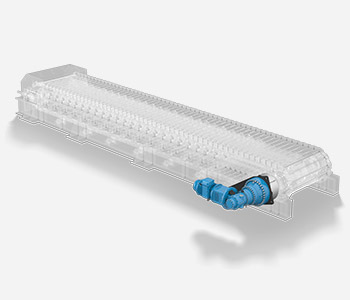

Apron feeders are necessary whenever the application requires a uniform flow of dry or moist fractions of rock […]

In order to crush ore, roller presses, or high-pressure grinding rolls (HPGR), utilize two counter-rotating rolls – one […]