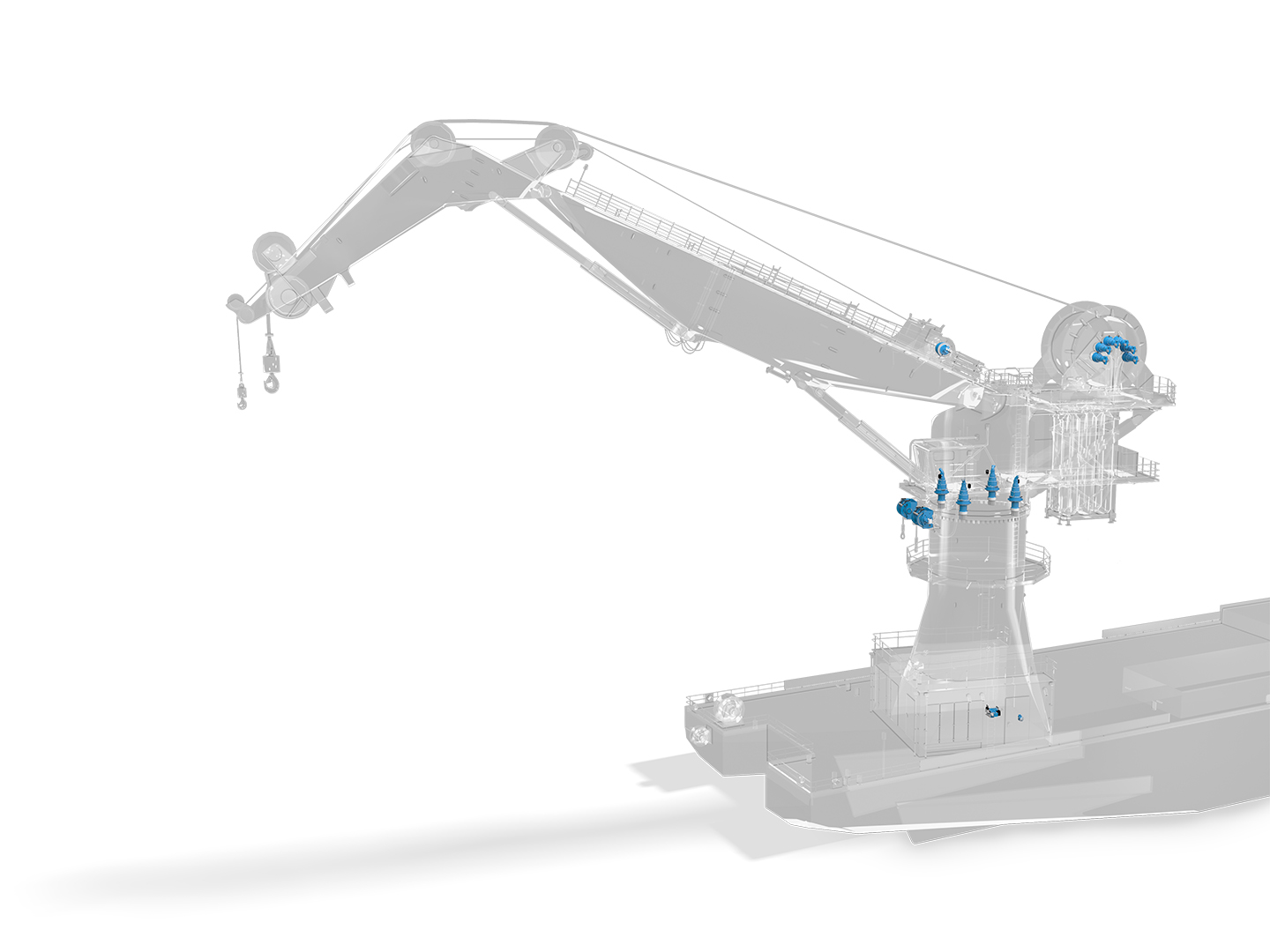

Deck Crane

As deck cranes for offshore applications need to be able to manage several hundred tons, often while ships are floating in a stormy sea, Dana is careful to work closely with a customer to find the ideal solution in terms of performance and safety. Customizable design options include hydraulic and electric drivelines; telescopic, knuckle, or lattice booms; a range of control system features to improve accuracy; and environmental features to optimize performance based on working conditions.

Working to ensure that local standards are met, as well as regulations set by the International Association of Classification Societies (IACS), Dana fulfills the requirements and delivers the long-term answer.

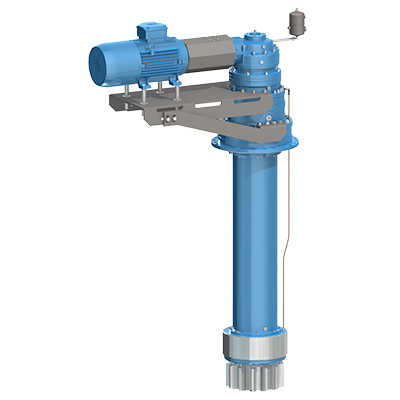

- Marine painting cycle

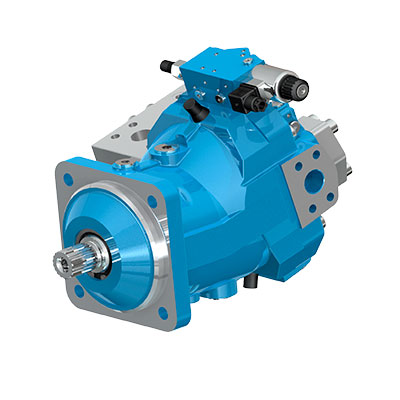

-Fixed and variable displacement

- Displacement up to 216 cc/rev

- Seven or nine piston options technologies

- Wide range of control valves

- Third-parties marine and ATEX certification

- Environmentally acceptable lubricants (EAL fluids)

- Suitable for working in harsh and aggressive environments

- High modularity

- ATEX certification

- Remote control, electronic operation

- Smooth control co improve operation functionality and accuracy

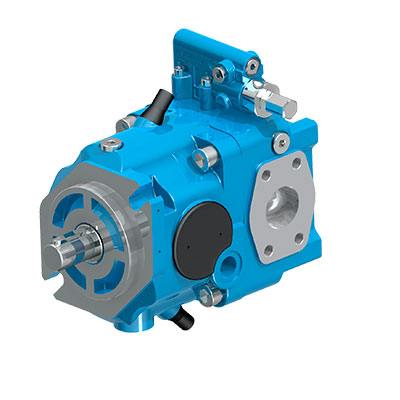

- Medium- and high-pressure options

- Fixed and variable displacement available

- Open or closed loop circuit

- ATEX certification

- Environmentally Acceptable Lubricants (EALfluids)

- Suitable for working in harsh and aggressive environments

- Ratio range up to 5.000:1

- Modular design

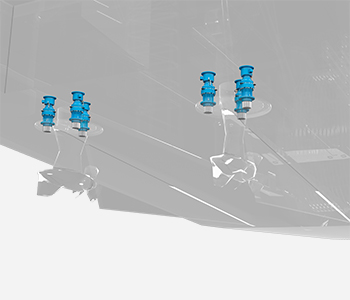

- Input flange for hydraulic or electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Marine painting cycle

- Third-parties marine certification available

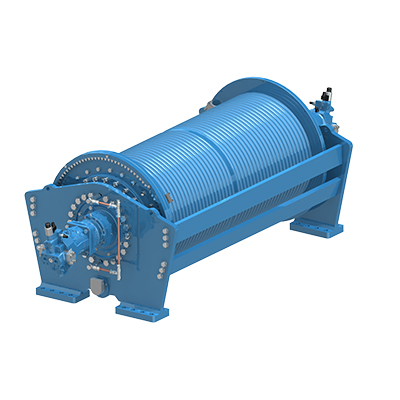

- Ratio range up to 6.000:1

- Maximum torque up to 850 kNm

- Third-parties marine certification available

- Inline and right angle configuration versions available

- Electric motor connection available

- ATEX certification

- Integrated hydraulic failsafe negative brake and electromagnetic brake available

- Safety devices available as back stop, torque limiter, and sensors

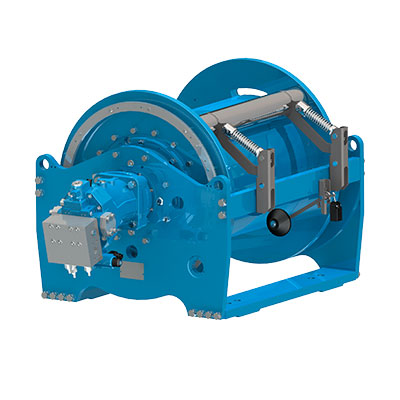

- Line pull up to 30 tons

- Third-parties marine certification available

- Wide range of safety controls

- Equipped with Brevini® high speed axial piston motor

- Man-lifting capabilities

- Modular design, inline or right angle configuration

- Range of output support configurations (low angle, long and short support with eccentricity)

- Failsafe negative brakes

- Input flange for hydraulic and electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Flexible output pinion to meet customer needs

- Product marine/offshore class certification available

- Special solutions to meet requirements for low climate and ATEX certifications

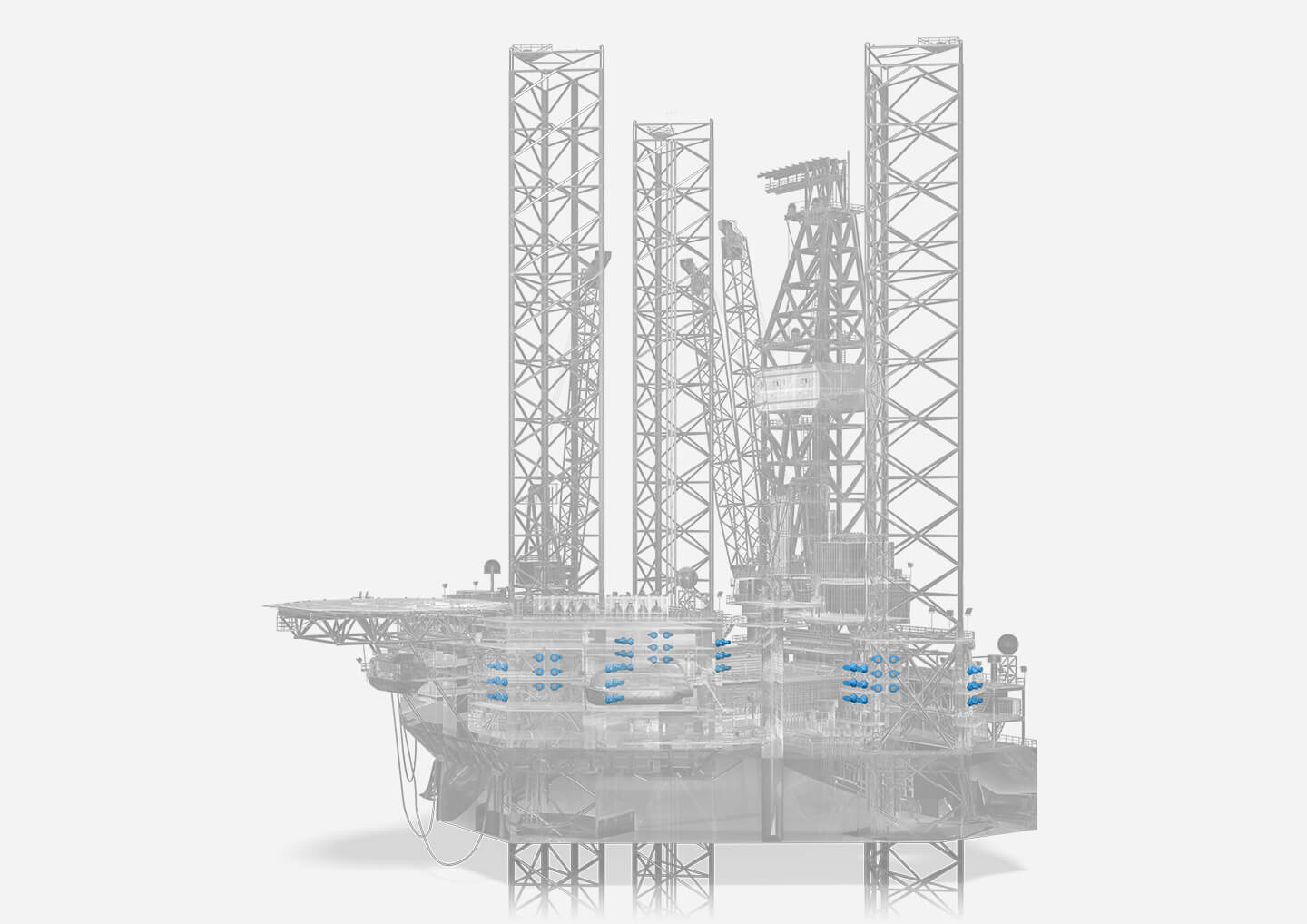

Market related applications

For more than 40 years, Dana’s Fairfield® brand has been engineering and building gearboxes for jacking machinery used […]

Cable and pipe-laying tensioners

Both for cable-laying ships laying cable for electric power transmission and telecommunications as well as for pipe-laying ships […]

A perfect propulsion solution for cruise ships, mega yachts, ferries, and other offshore vessels, azimuth thrusters incorporate a […]