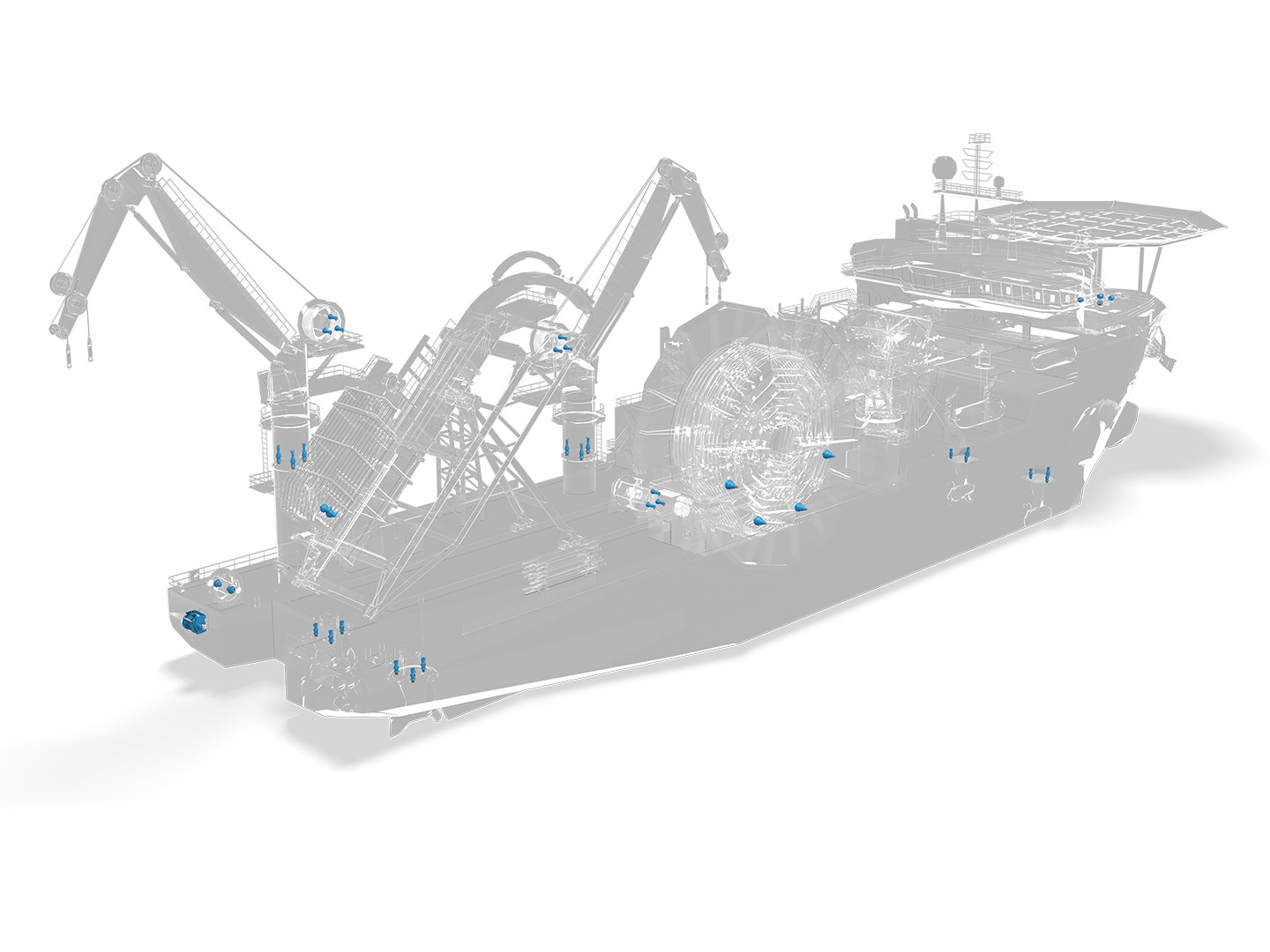

Cable and pipe-laying tensioners

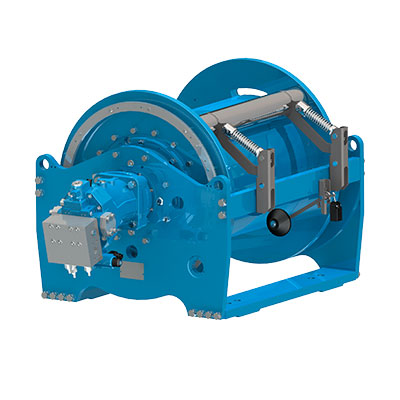

Both for cable-laying ships laying cable for electric power transmission and telecommunications as well as for pipe-laying ships used in the construction of subsea infrastructure for the oil and gas industry, Dana provides solutions for the grapple system (tensioner). This ensures that the cable or pipe is laid properly, and can retrieve damaged or misplaced sections from the ocean floor.

MACHINE DETAILS

- Line pull up to 30 tons

- Third-parties marine certification available

- Wide range of safety controls

- Equipped with Brevini® high speed axial piston motor

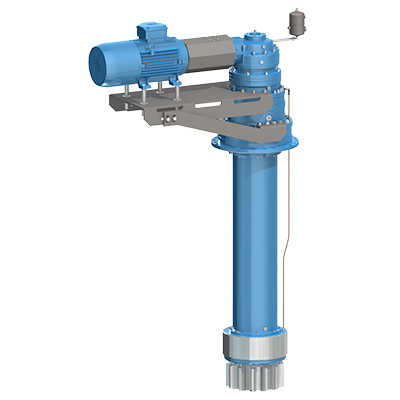

- Man-lifting capabilities

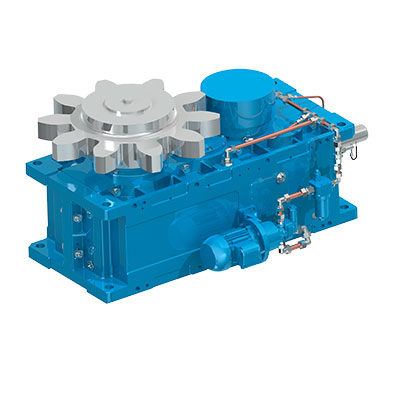

- Ratio range up to 6.000:1

- Maximum torque up to 850 kNm

- Third-parties marine certification available

- Inline and right angle configuration versions available

- Electric motor connection available

- ATEX certification

- Integrated hydraulic failsafe negative brake and electromagnetic brake available

- Safety devices available as back stop, torque limiter, and sensors

- Ratio range up to 6.000:1

- Maximum torque up to 850 kNm

- Third-parties marine certification available

- Inline and right angle configuration versions available

- Electric motor connection available

- ATEX certification

- Integrated hydraulic failsafe negative brake and electromagnetic brake available

- Safety devices available as back stop, torque limiter, and sensors

- Ratio range up to 5.000:1

- Modular design

- Input flange for hydraulic or electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Nominal torques up to 26,000 Nm

- Inline and right angle configurations available

- Suitable for both hydraulic and electric motors

- Integrated motor adaptor

- Negative multidisc brake

- Nominal torques up to 2,170 kNm

- Multiple output shaft options

Inline and right angle configurations available

- Suitable for both hydraulic and electric motors

- Negative multidisc brake

- Supports torque range up to 2200 kNm

- Extensive ratio range

- Special output shaft and bearing

- Forced lubrication system with double motor

pump and bypass

- Integrated electromagnetic brake

tooting profile

- Output support with eccentricity for a very accurate teeth

backlash adjustment

- Integrated safety device options (torque limiter, switches, sensors)

- Environmentally Acceptable Lubricants (EAL fluids)

- Pollution free regulations

tooting profile

- Output support with eccentricity for a very accurate teeth

backlash adjustment

- Integrated safety device options (torque limiter, switches, sensors)

- Environmentally Acceptable Lubricants (EAL fluids)

- Pollution free regulations

- Ratio range up to 5.000:1

- Modular design

- Input flange for hydraulic or electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Marine painting cycle

- Third-parties marine certification available

- Ratio range up to 5.000:1

- Modular design

- Input flange for hydraulic or electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Marine painting cycle

- Third-parties marine certification available

- Ratio range up to 5.000:1

- Modular design

- Input flange for hydraulic or electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Marine painting cycle

- Third-parties marine certification available

- Modular design, inline or right angle configuration

- Range of output support configurations (low angle, long and short support with eccentricity)

- Failsafe negative brakes

- Input flange for hydraulic and electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Flexible output pinion to meet customer needs

- Product marine/offshore class certification available

- Special solutions to meet requirements for low climate and ATEX certifications

- Modular design, inline or right angle configuration

- Range of output support configurations (low angle, long and short support with eccentricity)

- Failsafe negative brakes

- Input flange for hydraulic and electric prime motor

- Compact, light solutions for a perfect fit on machine frames

- Flexible output pinion to meet customer needs

- Product marine/offshore class certification available

- Special solutions to meet requirements for low climate and ATEX certifications

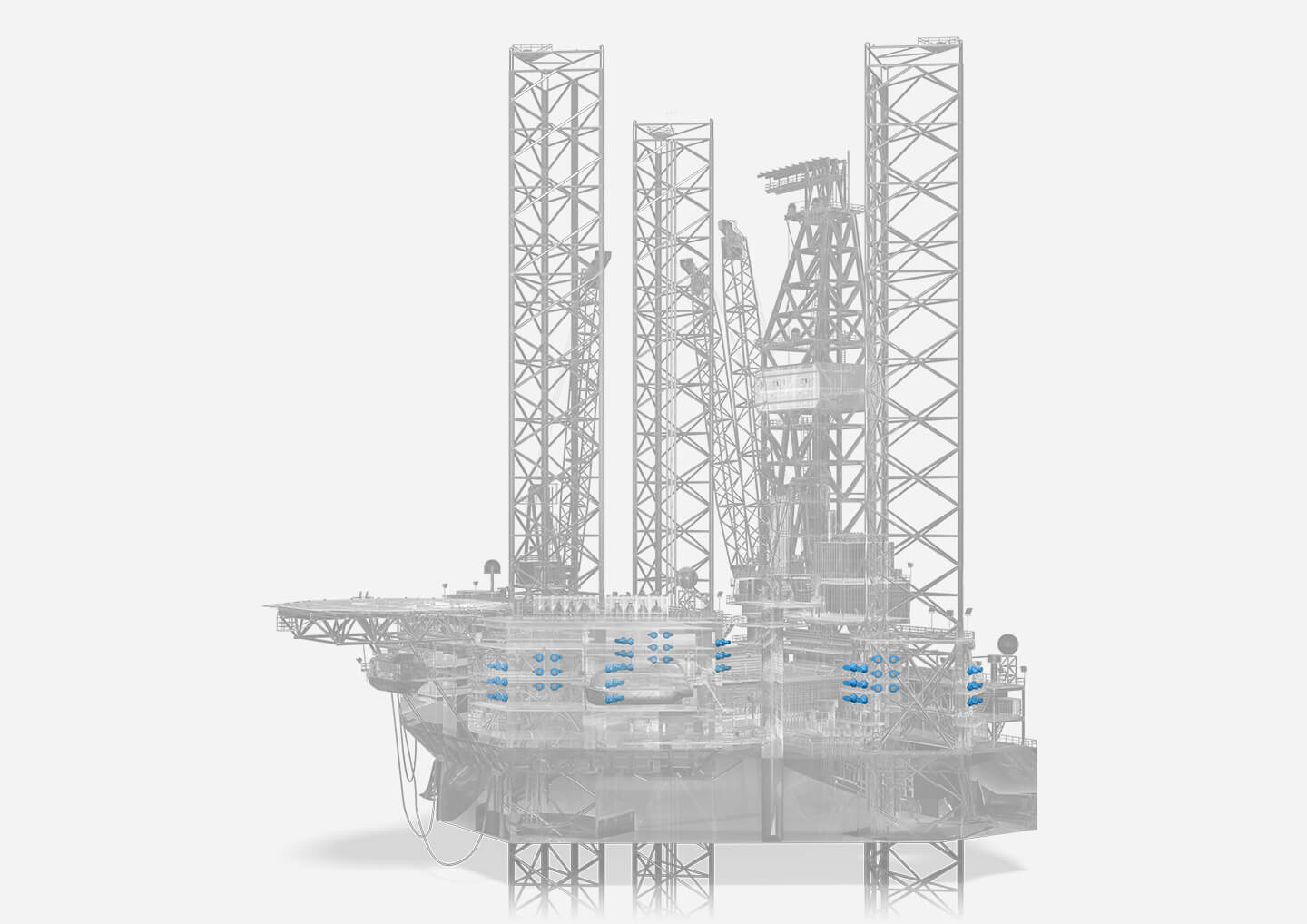

Market related applications

For more than 40 years, Dana’s Fairfield® brand has been engineering and building gearboxes for jacking machinery used […]

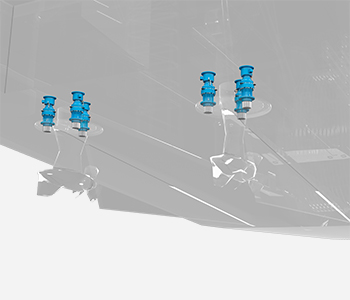

A perfect propulsion solution for cruise ships, mega yachts, ferries, and other offshore vessels, azimuth thrusters incorporate a […]

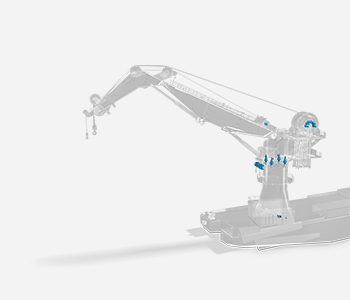

As deck cranes for offshore applications need to be able to manage several hundred tons, often while ships […]