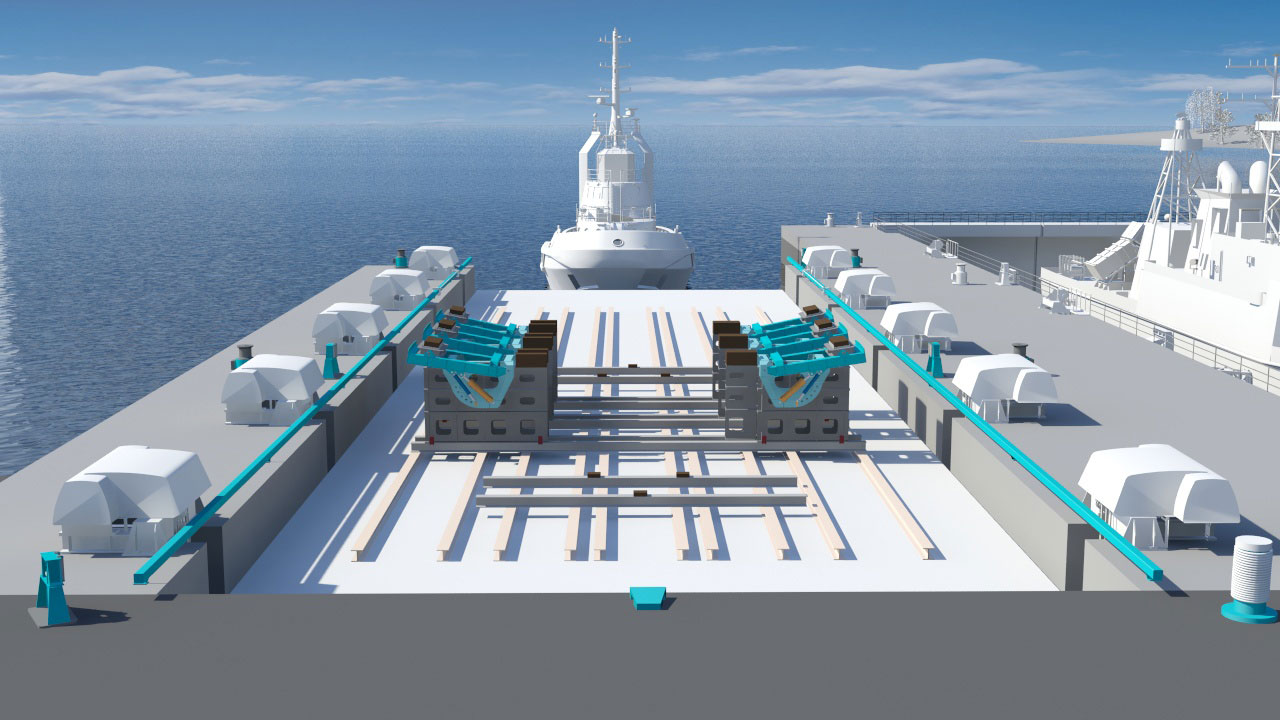

Ship lifting systems are used displace vessels from the sea into a dry dock for maintenance or refurbishment. The lifting equipment consists of a series of Dana Brevini hoisting winches according the capability of the system. The pulling capacity of a single winch is usually 45-50ton referred to line pull and 350-400ton as total pull at the hook; the higher the system capacity, the bigger the number of the winches. To increase safety twin winches operate in tandem at each side of lifting station: in case of failure of one unit, the twin one will be able to complete the lifting duty alone.

Once the vessel has been lifted from the rig, a transport system, either on railway and steel wheels or on rubber-tyred wheels -but always equipped with Dana Spicer wheel drives-, will take care of the ship and recover it into the dry dock.

This system enables shipyards to have just one water gate to serve multiple dry working docks, and thus servicing more vessels simultaneously, instead of the “classic” water docks, one for each ship in maintenance/refurbishment, increasing the performances and capabilities of the shipyard and together reducing fixed costs.

Dana Brevini is a global partner with more than 20 years of experience, working together with the major players in the sector, able to design and deliver the complete package, whatever a winch system or just mechanical and hydraulic drive, as well as special submersible executions for the trolleys, purposely designed with dedicated sealings and paintings resistant to salty environment.