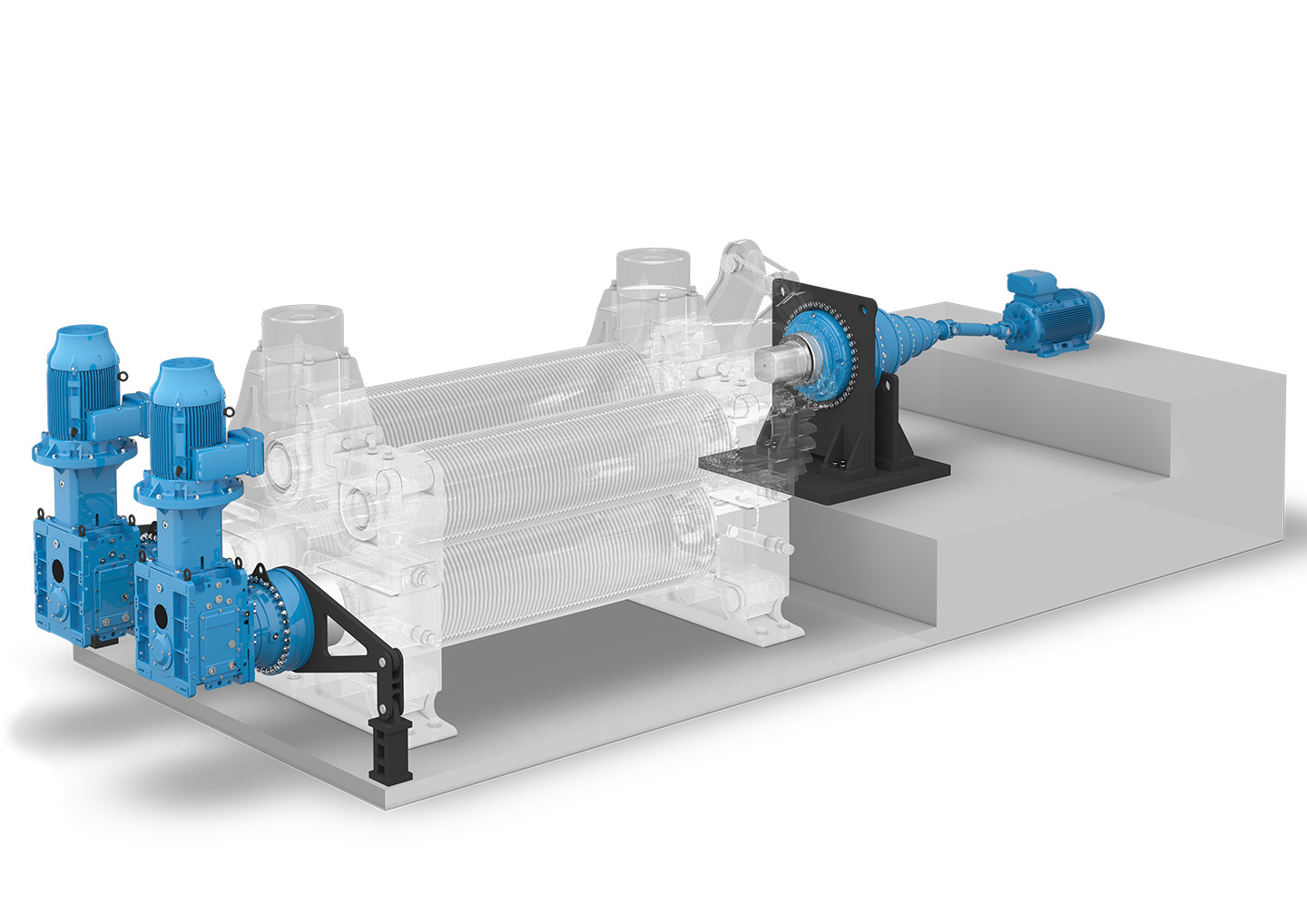

Sugar mill – multiple drive

When the sugar cane reaches the sugar mill, it is shredded to break down the fibrous stalks and burst open the juice cells. Subsequently the raw material is crushed using multiple roller drives. This enables the extraction of the molasses, a black treacly substance, leaving the fibrous leftovers. Once the juices are separated, any impurities are removed in a clarifier.

MACHINE DETAILS

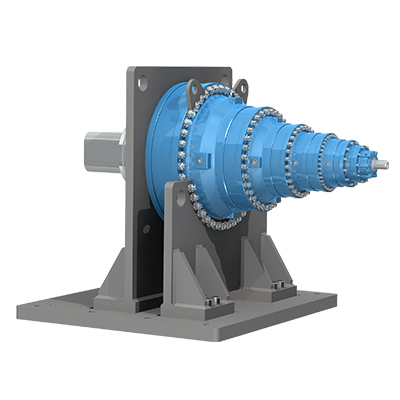

1

- Double torque arm with load cell included

as option for the electric driven

- Modular concept

- Extensive ratio range

- Supports torque range up to 2200 kNm

- Increased thermal capacity due to large

bevel set

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Low noise

- IEC flanges up to 355 size

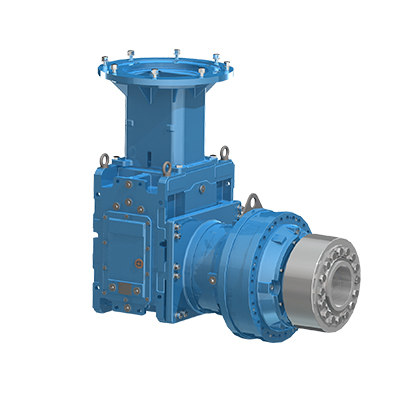

2as option for the electric driven

- Modular concept

- Extensive ratio range

- Supports torque range up to 2200 kNm

- Increased thermal capacity due to large

bevel set

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Low noise

- IEC flanges up to 355 size

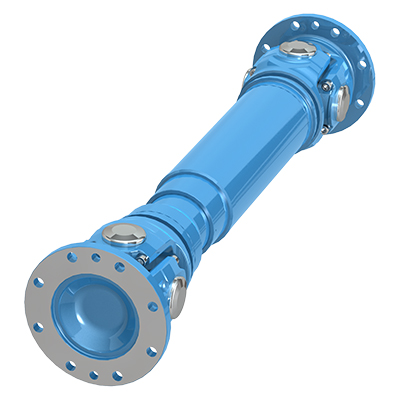

- Extensive ratio range

- Supports torque range up to 2200 kNm

- Increased thermal capacity due to shared oil chamber

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Low noise

- Customized male shaft with keyway

3- Supports torque range up to 2200 kNm

- Increased thermal capacity due to shared oil chamber

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Low noise

- Customized male shaft with keyway

- Complete product range featuring flange/swing diameter from 120 to 1300 mm

- Superior bearing life

- High torque capacity

- Designed for ease of maintenance with

service-free option

- Engineered to withstand harsh conditions, proven with a 70-year history on the market

- Minimized total cost of ownership

- Superior bearing life

- High torque capacity

- Designed for ease of maintenance with

service-free option

- Engineered to withstand harsh conditions, proven with a 70-year history on the market

- Minimized total cost of ownership

Market related applications

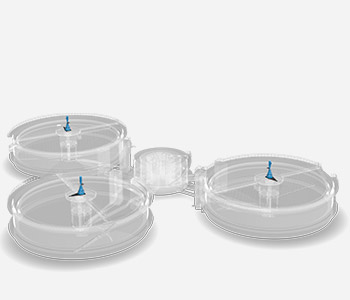

Clarifier-Crystallizer-Thickener

ClarifierThe principal task of a clarifier or juicer is to separate the solids from the sugar cane liquid in order to minimize […]