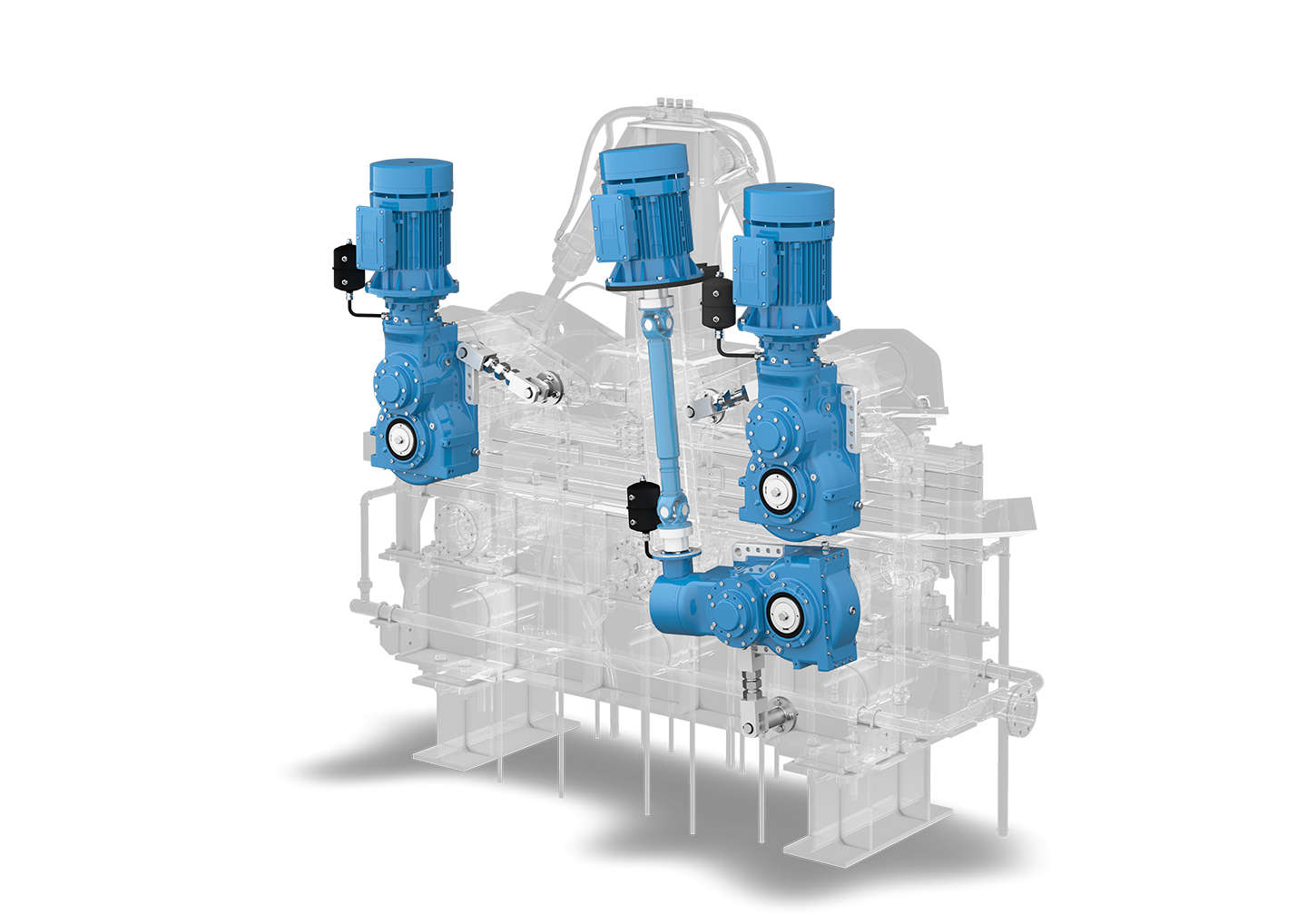

Straighteners

Straightener machines are used in the continuous casting process. During continuous casting, molten steel is solidified into semi-finished billets, blooms or slabs for subsequent rolling in finishing mills. Straighteners ensure the semi-finished product is straight and, by controlling the speed of the steel as it runs through the rollers, optimizes the quality of the billet, bloom or slab. There are different configurations, and different products and relevant sizes will define the number of rolls, how many of them are to be driven and the electric motor power. Gearboxes are generally equipped with cooling coils to cool down the gearbox oil.

MACHINE DETAILS

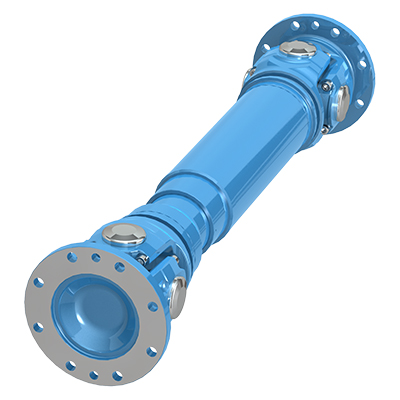

- Spheroidal graphite cast iron housing

- Supports torque range up to 40 kNm

- High efficiency

- Premium sealing

- Easy to assemble/disassemble

- Superior bearing life

- High torque capacity

- Designed for ease of maintenance with service-free option

- Engineered to withstand harsh conditions, proven with a 70-year history on the market

- Minimized total cost of ownership

Market related applications

A calender is a series of hard pressure rollers used to finish or smooth a metal sheet, also used in […]

Plastic deformation of a metal sheet can be performed cold or hot on a bending machine. Deformation results in a […]

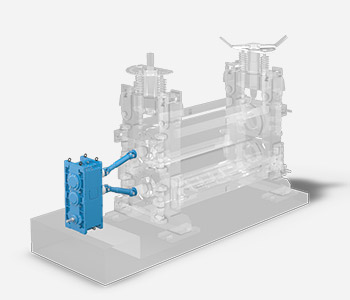

Edging drives, usually found at the start of the rolling process, are used to reduce the width of […]

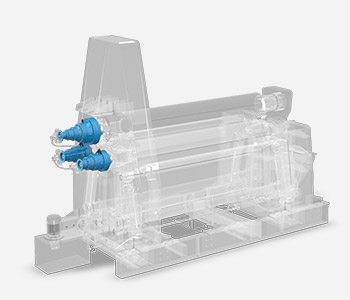

Down coilers wrap the strip at the end of the line after passing the finishing stands. Having different demands […]