Milling and Grinding

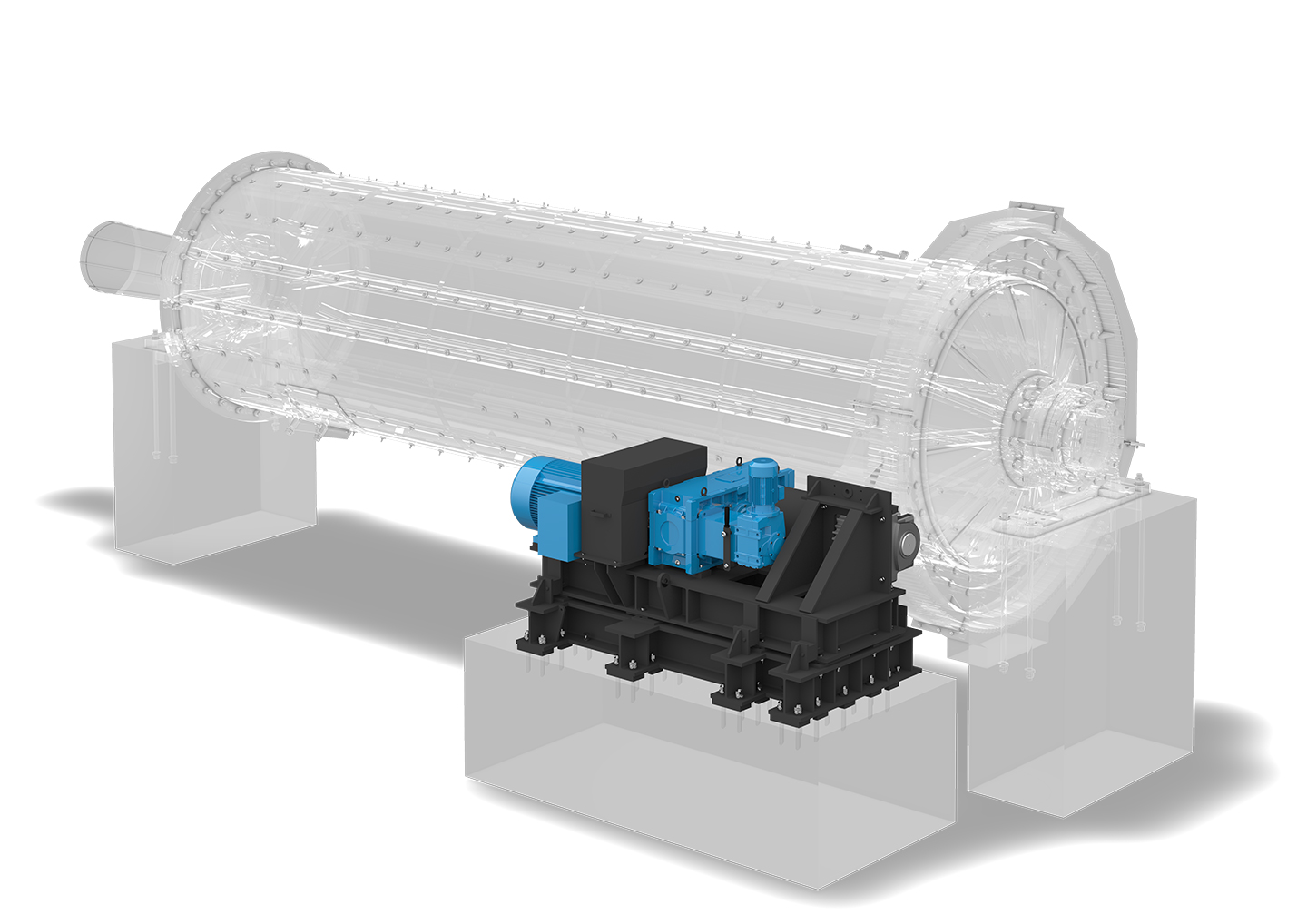

Horizontal mills

Horizontal mills, which are essentially large cylinders rotating horizontally or at a slight angle, mostly contain steel balls, although some mills use ceramic or rubber balls, which reduce the clinker to powder through impact and attrition.

Hydraulic Roller Presses

Hydraulic roller presses use two rollers, one of which is fixed, the other is adjusted using hydraulic pressure. Material is crushed as it passes between the rollers to the desired particle size.

Vertical Roller Mills

Vertical roller mills reduce material using the principle of mill stones, whereby vertical pressure exerted by the rollers, as they rotate in a circle, grind the clinker by crushing it onto the horizontal disc beneath.

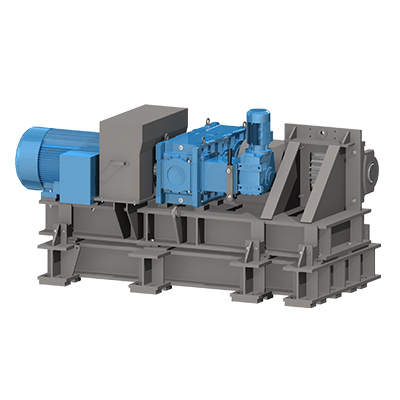

MACHINE DETAILS

1

- Complete drive system including base and bed plate

- Supports torque range up to 1300 kNm

- Spheroidal graphite cast iron housing

- High efficiency

- Premium sealing

- Reliable operation

Low noise

Dana with a high level network of partner is able to supply you the complete (all components) drive package as couplings, motors, engage and disengage systems.

- Supports torque range up to 1300 kNm

- Spheroidal graphite cast iron housing

- High efficiency

- Premium sealing

- Reliable operation

Low noise

Dana with a high level network of partner is able to supply you the complete (all components) drive package as couplings, motors, engage and disengage systems.