GEARBOX REPAIR

This service covers virtually all makes, models and styles of gearbox, even over 30 tons in size. Whatever your industry, our team will advise and agree on the best solution for you.

LOOSE GEARING

We manufacture gears and are equipped to reverse engineer the gearing at our facility. Original equipment replacements are also cut for third party outfits handling repairs independently.

FIELD SERVICE

We ensure on-site intervention with a dedicated field service team dealing with inspection, installment and commissioning. This service is ready to handle breakdown situations 24/7.

GEARBOX REPAIR

This service covers virtually all makes, models and styles of gearbox, even over 30 tons in size. Whatever your industry, our team will advise and agree on the best solution for you.

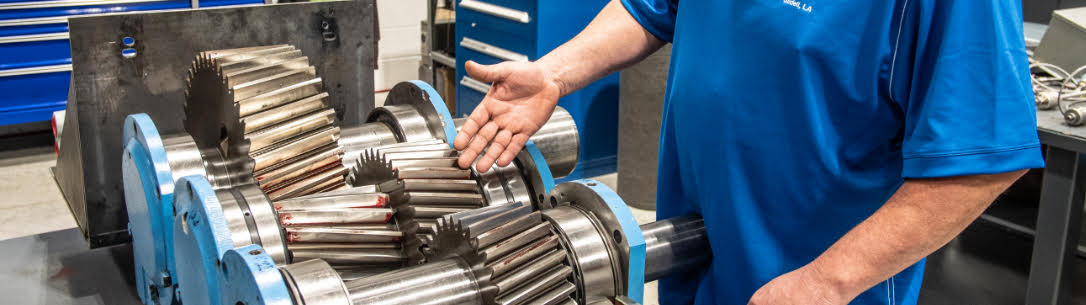

LOOSE GEARING

We manufacture gears and are equipped to reverse engineer the gearing at our facility. Original equipment replacements are also cut for third party outfits handling repairs independently.

FIELD SERVICE

We ensure on-site intervention with a dedicated field service team dealing with inspection, installment and commissioning. This service is ready to handle breakdown situations 24/7.

LIKE NEW REPAIRS AND UPGRADES

Gearboxes are repaired to better-than OEM standards, with appropriate warranties, and to enjoy maximum performance, we also suggest evaluating a series of upgrade options, even customized to bring you additional benefits.

WORLDWIDE SUPPORT 24/7

Our service department is available 24/7, and our qualified global network provides customer service and support around the clock.

Call on +1 – 985 – 445 – 1717

TIMELY AND ECONOMICAL REPAIRS

Minimizing downtime reduces the economic impact of a stoppage, so we do everything we can to repair your gearbox as fast as possible, working around the clock or, in critical situations, moving you to the front of the line.

Four factors make Slidell the top tier gearbox repair facility for the North American market. The Plant with its cutting-edge machinery, the People with their vast experience, the consolidated repair Process and the Performance we ensure.

TAKE A TOUR

OF OUR FACILITIES

The Slidell facility measures over 32,000 sq. feet and features machinery able to handle just about any size or style of gearbox, as well as manufacturing capabilities that answer the need to immediately solve a requirement in-house.

MEET MEMBERS

OF OUR TEAM

Listen to the People from Dana SAC North America as they reveal a few insights into the Repair Formula implemented at Slidell. Discover their role and specific expertise, and how they make a difference when responding to your requirements.

Four factors make Slidell the top tier gearbox repair facility for the North American market. The Plant with its cutting-edge machinery, the People with their vast experience, the consolidated repair Process and the Performance we ensure.

TAKE A TOUR

OF OUR FACILITIES

The Slidell facility measures over 32,000 sq. feet and features machinery able to handle just about any size or style of gearbox, as well as manufacturing capabilities that answer the need to immediately solve a requirement in-house.

MEET MEMBERS

OF OUR TEAM

Listen to the People from Dana SAC North America as they reveal a few insights into the Repair Formula implemented at Slidell. Discover their role and specific expertise, and how they make a difference when responding to your requirements.

The most frequent and critical issue we address is getting your operations back up and running in the shortest time possible and at a reasonable cost.

With a plant equipped to manufacture loose gearing, we rarely need to depend on external suppliers and we are able to speed up repair times by controlling the process in-house.

It is not uncommon to be faced with a breakdown situation or one requiring on-site intervention and the fastest possible solution to minimize downtime and loss in production.

DISCOVER OUR SERVICES

The most frequent and critical issue we address is getting your operations back up and running in the shortest time possible and at a reasonable cost.

This entails understanding your situation, combining that with our extensive gearbox knowledge and using our full resources to deliver the best solution. Frequently an exact drop-in replacement is not possible, so we are equipped to repair virtually any gearbox and even handle sizes in excess of 30 tons. Performing hundreds of repairs annually, we cover industries ranging from steel to chemical, mining to grain processing, and many more.

With a plant equipped to manufacture loose gearing, we rarely need to depend on external suppliers and we are able to speed up repair times by controlling the process in-house.

We have a gear hobber and a 2-meter gear grinder to make new parts, plus we are fully equipped to reverse engineer the gearing after performing detailed analysis. Loose gearing manufacturing is also a service we offer third party companies handling repairs independently. We also manufacture shafts and other components in-house to make the process faster, more economical and better suited to your needs.

It is not uncommon to be faced with a breakdown situation or one requiring on-site intervention and the fastest possible solution to minimize downtime and loss in production.

We have a team that will deploy 24/7 to make the initial assessments and intervene directly if this will solve the issue or whenever equipment cannot be moved from your plant. This team answers hundreds of calls annually and is fully equipped to handle repairs in the shortest time possible, even working round the clock to avoid unnecessary downtime. Field service also includes laser alignment, vibration analysis and start-up commissioning for new or repaired units.

DISCOVER OUR CASE STUDIES

GEARBOX REPAIRS

Our approach to gearbox repairs goes beyond your aim to just start your equipment working again. We make it work better. Discover how we dealt with recurrent bearing failure on a dredging vessel, solving the issue for good.

LOOSE GEARING

Our in-house manufacturing capabilities for loose gearing are proving to be a turn-key solution for many customers. Discover how we replaced large 1DP mill pinions at a chemical manufacturing facility recently.

FIELD SERVICE

We can never stress the importance of regular inspections enough. Our Field Service team recently saved millions of dollars in avoidable repairs to a ball mill. Discover how we prevented a cement company suffering the consequences of imminent bearing failure.

GEARBOX REPAIRS

Our approach to gearbox repairs goes beyond your aim to just start your equipment working again. We make it work better. Discover how we dealt with recurrent bearing failure on a dredging vessel, solving the issue for good.

LOOSE GEARING

Our in-house manufacturing capabilities for loose gearing are proving to be a turn-key solution for many customers. Discover how we replaced large 1DP mill pinions at a chemical manufacturing facility recently.

FIELD SERVICE

We can never stress the importance of regular inspections enough. Our Field Service team recently saved millions of dollars in avoidable repairs to a ball mill. Discover how we prevented a cement company suffering the consequences of imminent bearing failure.

REQUEST MORE INFORMATION

Please fill in the form below to obtain more information.