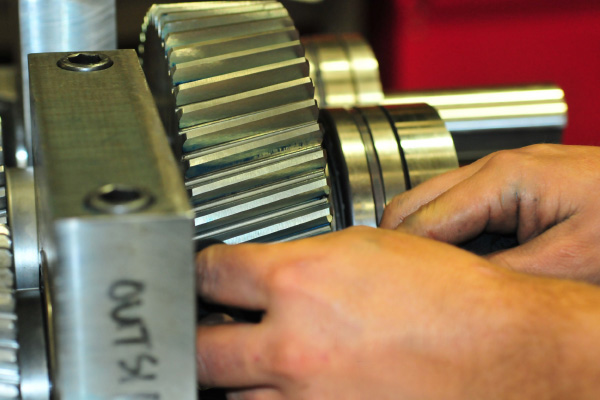

All makes, all models, all types

With more than twenty years of experience of repairing, servicing and reconditioning industrial gearboxes from almost all sectors and manufacturers, we have a vast pool of technical knowledge and understanding to draw upon.

This expertise is augmented by the world-class technical resources available from Dana, who have unrivalled experience of both new product design and manufacture.

- Strong, proven team of application engineers working to the very highest professional standards

- Meticulous, systematic approach with all steps fully documented, costed and supported by photographic evidence

- Reverse engineering of parts where necessary

- All rebuilt units spin tested