Bulk Material handling

STACKER RECLAIMERS

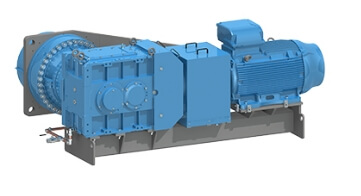

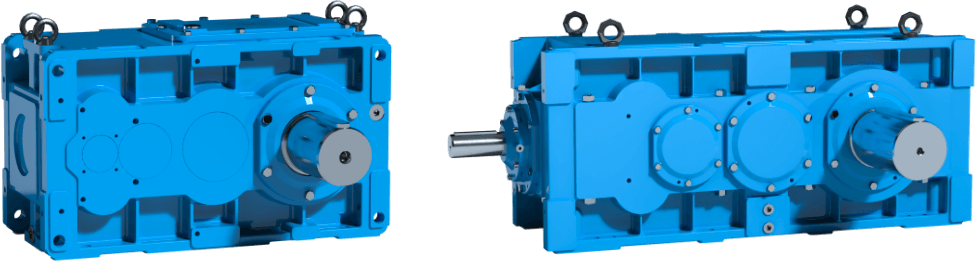

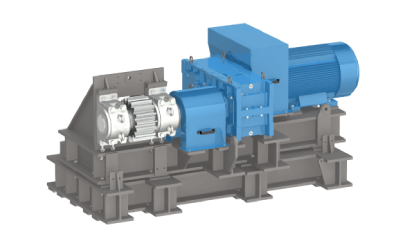

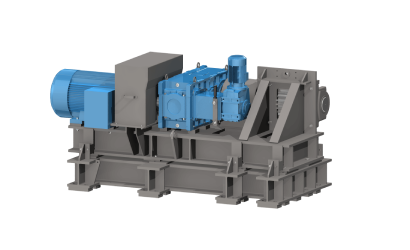

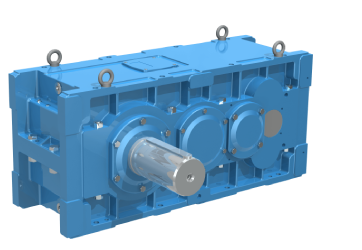

Solutions for conveyors, boom hoists and bucket wheels. When handling bulk materials, working conditions and application-specific factors are carefully evaluated by our team. The resulting package is a complete solution where we can customize to best suit your needs. For example, by combining a planetary gearbox to a bevel helical gearbox offering a more compact solution in high power applications, maximizing thermal capacities, we are able to offer a cost-effective answer which is efficient both in terms of space and delivered torque.